Why Your Supply Chain AI Implementation Sucks

How to Make Supply Chain AI Implementations Actually Work

Too many organizations try to “bolt-on” ChatGPT onto existing workflows, those workflows are clunky, inefficient, outate an are no longer fir for purpose in a digitalized business world. Let me brutally honest, this is a bit like attempting to strap a jet engine onto a horse drawn carriage…no matter how you do it, it just ain’t going to work.

The Great AI Mirage

Ever since the launch of ChatGPT in late 2022, executives have been tripping over themselves to declare that AI will “revolutionize” their supply chains. Three years on in early 2026 most are still staring at Excel spreadsheets, firefighting shortages, and wondering why their “AI transformation” feels more like a PowerPoint placebo.

The truth is you’re not failing because your AI tools are weak. You’re failing because you haven’t torn up the rulebook. You’ve digitized the past instead of inventing the future you want.

You’ve taken all the “old stuff”, that didn’t really work very well in the first place and you’ve tried to adapt the AI to what is basically a never-ending burning dumpster fire.

Here’s the reality, big productivity gains from AI don’t come from adding intelligence to broken, crappy, disjointed workflows. They come from rebuilding those workflows from the ground up with AI built into their very foundations. It is the AI that needs to be the overarching process architect for the work it is intended to do, after all, nobody likes a backseat driver.

The AI is not the side-show it is the headline event and the people that oversee it, are the “MCs”. They are inseparable and cannot function effectively without each other. Ultimately, if its purely about reducing the workforce, failure is pretty much guaranteed.

Organizational Re-engineering in an AI-native Paradigm

This is not a wax-on, wax-off, exercise, we’re talking about organizational re-engineering in an AI-native paradigm. This involves fundamentally redesigning the company’s structure and processes to fully integrate AI into its operations.

This means creating workflows and business models that leverage AI capabilities from the start (not as an after-thought), rather than just adding AI tools to existing systems. This is the key that opens the door to a whole new world of potentiality and possibilities, it is a catalyst for more efficient and innovative ways of working.

Let’s Add a Rocket Motor to a Rickshaw

AI is a tool for the people, by the people, and with the people.

Most companies treat AI like a plug-in module. They buy a shiny new AI-infused demand forecasting model, drop it into their legacy ERP, and expect miracles. But here’s the uncomfortable reality; AI doesn’t scale inside legacy processes, it just suffocates.

Think of it this way, if your planning cycle still runs on monthly S&OP meetings, manual Excel spreadsheet-driven overrides, and tribal knowledge passed over badly made, luke-warm trendy coffee, no amount of machine learning will save you. AI needs autonomy, real-time data, and decision rights to be effective, the fact is, legacy structures, processes, and procedures offer none of these.

As the old saying goes; “you can’t make a silk purse of a sows ear.” A 2025 McKinsey study found that only 12% of companies achieved >20% ROI from AI initiatives and every single one had redesigned core workflows before deploying AI. Anything else is nothing more than automated inefficiency.

The AI-Native Supply Chain

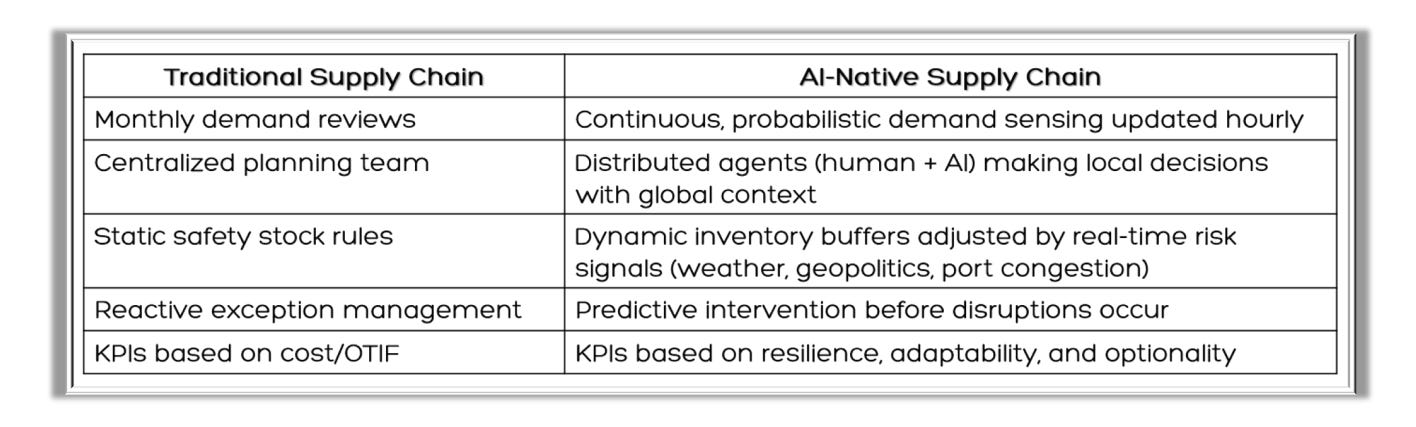

It’s a departure from what you’re used to. An AI-native supply chain isn’t just faster, it’s structurally different. Roles shift. Decisions decentralize. Feedback loops compress from weeks to seconds. My table below compares, at a high level, traditional supply chains versus AI-native ones.

Notice something? In the AI-native model, people don’t disappear, they are elevated. Planners become “*orchestrators,” interpreting AI recommendations, injecting strategic intent, and managing edge cases. But that only works if you’ve redesigned the job itself.

A 2024 MIT Sloan analysis revealed that companies that redefined roles before AI rollout saw 3.2x higher adoption rates and 47% fewer process breakdowns.

Organizational Culture Can Break it or Make it

You can have the best AI model in the world but if your culture rewards heroic firefighting over proactive prevention, if managers punish “wrong” AI-driven decisions but praise gut-feel wins. If collaboration is merely lip service while silos remain fortified, that’ll make your AI a glorified, albeit expensive door-stop.

AI thrives in cultures of psychological safety, data humility, and iterative learning, think the learning organization characteristics here. Yet most organizations supply chains still operate on command-&-control hierarchies built for predictability, not volatility and uncertainty.

Consider this, a 2025 Gartner survey showed that 68% of supply chain leaders said “lack of cultural readiness” was the top barrier to AI value realization not data quality, not tech stack, not budget.

Its Not About Technology Its About Architecture

Before we get into this further I would like you to keep something in mind. Too many organizations have not fully mapped their end-to-end supply chain processes. And if they have, they are very likely be inaccurate, and are not detailed enough. The fact is, what they think is happening and what is actually happening, are two entirely different things.

So, stop asking; “how do we use AI in our current process?”

And start asking; “if AI were designing this process from scratch, what would it look like?”

That question forces you to confront a few uncomfortable truths:

Do we really need a 30-person planning team if AI handles 80% of routine decisions and can’t they be put to better use elsewhere?

Should procurement still be a gatekeeper or a risk advisor guided by real-time supplier health scores?

Can we replace static contracts with dynamic, AI-negotiated agreements that auto-adjust based on market conditions?

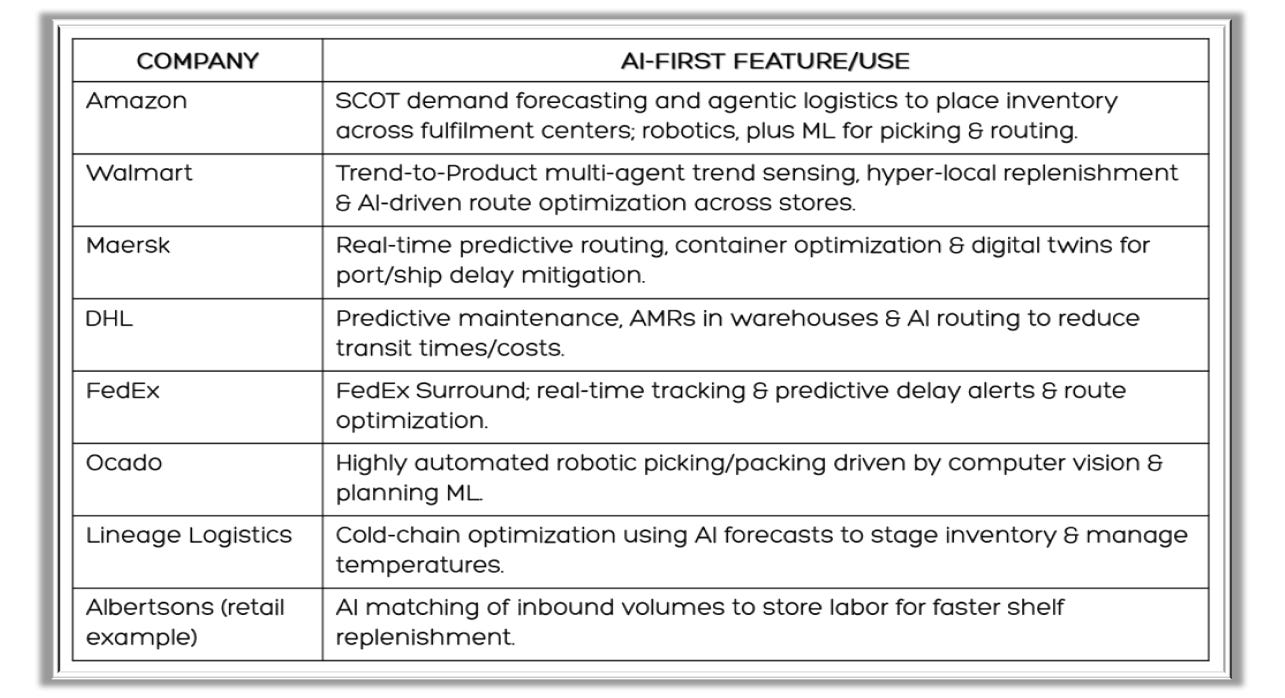

This isn’t theoretical. Companies like Maersk, Flexport, and Zara’s parent Inditex have already begun operating “AI-first” supply networks where human judgment is reserved for ambiguity, ethics, and strategy, not data entry.

AI-first Supply Chains

An AI‑first supply chain treats AI as the core decision engine, not an add‑on. AI continuously ingests internal and external data, senses demand/supply changes in real time. Recommends or automates corrective actions within predefined parameters, and closes feedback loops so models can steadily improve over time.

Key Characteristics

Data‑native: Integrated, governed data across ERP/WMS/TMS/external feeds.

Agentic & prescriptive: AI agents recommend or execute rebalancing, routing, procurement, pricing.

Real‑time orchestration: Planning and execution converge (digital twins, event‑driven workflows).

Autonomy with guardrails: Automated actions plus explainability, human override and governance.

Outcome focus: KPIs (service level, inventory turns, cost, emissions) drive model objectives.

Real World Examples

A Full Deconstruction & Reconstruction is Needed

The path forward isn’t incremental, it’s a revolutionary seismic change, to accomplish this one must:

Map your core workflows, not as they appear in org charts, but as they actually operate (spoiler: they’re messier than you think).

Identify decision chokepoints where latency kills value and hand those to AI.

Redesign roles so people have the space they need to focus on interpretation, exception handling, and relationship nuance.

Rewire incentives to reward learning from AI, not overriding it.

Pilot in reverse; start with the end-state AI-native process, then back-fill the transition not the other way around.

Remember; using AI in supply chains is not about “fixing” them. The focus must be on deconstructing the supply chain and rebuilding it with AI in mind, from the ground up. Its about the only proven way you’re going to implement it [AI] successfully.

If your supply chain processes, procedures and policies are crap from the get-go and if you think the use of AI is going to “fix it”, to put it bluntly, you’re out of your mind.

The Future Is Already Here

Its Just Unevenly Distributed

In 2026, the divide isn’t between AI adopters and laggards. It’s between those who grafted AI onto shaky foundations and those who had the courage to burn the blueprint, start from scratch and rebuild. The fundamental premise being, don’t build onto a foundation that isn’t fully optimized and properly tuned for the task.

One path leads to incremental disappointment dressed in buzzwords. The other unlocks a supply chain that anticipates, adapts, and acts before people even notice the need. Your choice isn’t about technology, it’s about legacy versus leadership. And frankly, your career may hinge on which side you choose.

I am a remote WFH logistics/supply chain specialist with over 25+ years of experience, if you could use my type of expertise please feel free to get in touch.

Further Reading

Some of my other related Substack Supply Chain articles.

“Let’s Talk About the SCM Leadership Paradigm: Leadership in the Era of Digitalized AI-Augmented Supply Chains” - link

“2026 The Supply Chain Evolution Continues: Understanding AI Orchestration & How to Get it Right” - link

“How AI is Affecting Supply Chain Job Roles: Traditional Roles & Responsibilities Are Changing” - link.

“Supply Chain Centaur Teams Explained: Bringing AI & People Together to Make Faster Smarter Higher Performing Supply Chains” - link

#SupplyChainAI #AINative #AIImplementation #ProcessReengineering #FutureOfSupplyChain #AIRealityCheck #AIOrchestration #supplychainmanagement #scm